FREE SHIPPING OVER $20

Free Shipping Inside The USA

MONEY BACK GUARANTEE

30-Day Money Back Guarantee.

MADE IN THE USA

100% American Made Products.

Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish

- Location : Interior/Exterior

- Task : Floors

- Application : Pump Sprayer, MIcrofiber Mop, T-Bar, Roller

- Base : Water Based Urethane

- Coverage : 800 sq.ft/ gallon (19 .6 sq.m/l)

- Finish : Matte

- Secure Checkout

- Location : Interior/Exterior

- Task : Floors

- Application : Pump Sprayer, MIcrofiber Mop, T-Bar, Roller

- Base : Water Based Urethane

- Coverage : 800 sq.ft/ gallon (19 .6 sq.m/l)

- Finish : Matte

Delivery Time: Typically 3 to 5 business days

Frequently Bought Together

Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish

$14.00 – $471.50Price range: $14.00 through $471.50

- Description

- Application

- Product Quantity Calculator

- Technical

- FAQs

- Reviews

Description

Gas And Oil Resistant Concrete Sealer - CoverShield U140 - Matte Finish

CoverShield U140, Matte Finish Video

CoverShield U140 Matte Finish Unboxing Video

Shelf Life

Theoretical Coverage

Key Takeaways for CoverShield U140 Gas And Oil Resistant Concrete Sealer - Matte Finish

- CoverShield U140 Matte gas and oil resistant concrete sealer is recommended for interior applications, trowel finished concrete, or smooth concrete.

- Oil can permanently stain concrete depending on the type of concrete and porosity of its capillaries.

- Sealing new or existing concrete with a film-forming sealer is highly recommended.

- CoverShield U140 Matte finish is a high solid content sealer that is hard-wearing and bonds well to the smooth, dense interior concrete surfaces.

- It provides extended clean up times, giving you more than 24 hours to deal with recent oil, gas, brake fluid, hydraulic fluid and other chemical spills.

- Store-bought topical sealers claim to be oil-resistant, but they only provide between 1 and 4 hours of stain resistance.

- For interior concrete, CoverShield U140 Matte is recommended, and it needs to soak into the surface and provide a thin, highly durable film over concrete.

- Your surface being treated needs to be clean, dry, and absorbent before applying CoverShield U140 Matte concrete sealer.

- When using CoverShield U140 Matte, no grinding or etching is needed.

Features

- Scratch resistant

- Oil and stain resistant

- Odorless

- UV stable

- Easy to apply

- Chemical resistant

- Waterproof

- Excellent abrasion resistant

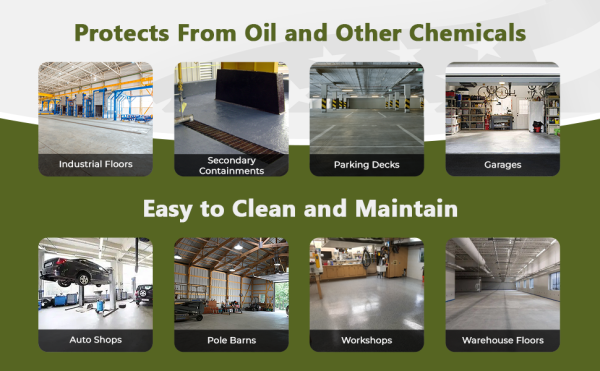

Typical Uses

- Industrial floors

- Parking decks

- Workshops

- Walkways, stairways

- Counter tops

- Driveways

Before And After Applying CoverShield U140 Gas And Oil Resistant Concrete Sealer - Matte Finish

Protect Your Surfaces Against Fuel Stains With CoverShield U140 Matte Gas And Oil Resistant Concrete Sealer

A Quick Breakdown of Key Points

What Is A Gas And Oil Resistant Concrete Sealer?

- A study published in 2020 found that polyurethane-based concrete sealers are among the most effective options for protecting against gas and oil penetration.

- Concrete sealed with a polyurethane-based sealer can typically resist fuel spills of up to 33 PSI (pounds per square inch) without compromising adhesion.

- According to research from 2020, acrylic- or epoxy-based concrete sealers can protect against water, salt, and mild acids but may not provide adequate protection against gasoline or other petroleum products.

The Benefits Of Concrete Protection

How Does A Sealer Work?

Protection From Harsh Chemicals

Penetrating The Surface

Top Takeaways

Bonding With Masonry And Substrates

Applying A Sealer To Concrete Surfaces

What To Look For In A Gas And Oil Resistant Concrete Sealer

Maintenance And Durability

Conclusion

Frequently Asked Questions Answered

Once the surface has been prepared, the next step is to carefully apply the gas and oil resistant sealer. Make sure to use painter’s tape to mask off any nearby finishes or surfaces that you don’t want to get sealer on, such as wood or metal finishing. As you’re applying, pay special attention to drips or runs that can affect the overall finish of your project. Use a brush to evenly spread out the sealer, and if needed use a roller for larger flat surfaces. Be sure not to get too much sealer on your project since it will become difficult to work with once it starts drying.

Once you have applied enough sealer for your project, allow it time to dry completely. With some types of sealers this can take up to 24 hours for full curing and full protection. Check around for potential puddles or runs that need touch-ups after the initial application and make sure you let it dry properly before walking on it or using any furniture on top of it.

Finally remember if you don’t use a gas and oil resistant sealer then never to let gasoline come into contact with a SEALED concrete surface as this could cause staining and discoloration that cannot be easily removed without causing further damage to your concrete slab/surface.

Using a gas and oil resistant concrete sealer can have numerous advantages. First and foremost, it helps to proactively protect the concrete surface from deterioration caused by gas and oil spills. Gasoline and motor oil contain compounds that can be very corrosive when they come into contact with a concrete surface. These liquids can cause damage, staining, and even discoloration of the concrete if not sealed properly. The gas and oil resistant sealer will provide an extra layer of protection against any damage that these substances may cause.

In addition, the sealer will also help to reduce maintenance costs associated with the concrete surface in the long run. If a spill were to occur, the sealer could make it easier to clean up and prevent further damage from occurring. In many cases, using this type of sealer can also increase the life expectancy of the concrete. This is because it helps to create an impermeable membrane on top of the concrete which will protect it from wear and tear over time.

Overall, using a gas and oil resistant sealer can provide numerous benefits for concrete surfaces. It provides much-needed protection against potential damage caused by gasoline and motor oil; it reduces maintenance costs; and in some cases, it may even extend the life expectancy of your concrete surface.

There are several types of concrete sealers that are resistant to gas and oil. The most common type is an acrylic sealer, which forms a water-resistant barrier on the surface of the concrete while still allowing it to breathe. Acrylic sealers are easy to apply and relatively inexpensive, making them a popular choice for sealing concrete.

Epoxy sealers provide more protection than acrylic sealers but come at a higher price. They form a hard, durable and chemical-resistant layer on the surface of the concrete, protecting against both water and oil/gas residues. They are also more difficult to apply than acrylic sealers and require special preparation before use.

Urethane sealers provide excellent protection from moisture and chemicals, including gas and oil. They’re highly durable and long lasting, but can also be more expensive than acrylic. However they are less costly than epoxy sealers. Siloxane sealers are also quite effective in sealing against water and natural elements with excellent adhesion to the concrete. They don’t do well as gas & oil resistant sealers,. Additionally, Siloxane sealers can penetrate deeper into the surface than most other types of seals, providing better overall protection from damage caused by water and salt attack mold and mildew.

CoverShield U140 Matte Videos

| Product Name | Surface Type | Coverage | Size of Area (sq ft) | Recommended Quantity |

|---|---|---|---|---|

Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish

|

Smooth Surface | 800 sq. ft. per gallon | ||

Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish Gas And Oil Resistant Concrete Sealer – CoverShield U140 Matte Finish

|

Textured Surface | 400 sq. ft. per gallon |

- The recommended amounts are approximate only, and are for One (1) application.

- Check product data for recommended number of applications.

- Test product on actual surfaces to determine exact coverage rates.

CoverShield U140 Matte Technical Data Sheet

CoverShield U140 Matte Cleaning and Maintenance Instructions

CoverShield U140 Matte Safety Data Sheet

U140 does not require extensive surface preparation in order to bond to a smooth surface. This makes the product very effective on smooth steel troweled, densified or polished concrete. The high coverage per gallon.( 800 sq. ft /gal or greater) compared to 150 -200 sq. ft per gal for an epoxy coating . This makes the U140 a high-performance high value solution. A lot of bang for the buck!

Epoxy coatings have excellent oil and chemical resistance but are not UV resistant and are for interior use only. Application thickness is higher and surface preparation needs are greater for an epoxy . This drives up the overall cost of and epoxy coating compared to the CoverShield U140.

Yes, U140 is very chemical resistant to a variety of substances you would see in a garage setting, for example brake fluid, oil, acid, bleach, salts, etc. We use a low viscosity highly crosslinked advanced blend of polyols resins in a water-based formulation. When these resins react together the thin film formed is highly resistant to oil and automotive fluids, acids, alkaline solutions, solvents, food stains and cleaning agents.

A major benefit of the CoverShield U140 is that it is a thin film system. It penetrates the sub surface and leaves a thin film on top of the concrete. This film is very oil resistant and makes concrete easy to clean and maintain. Also, it does not flake and peel like epoxy.

Having said that U140 is a very durable sealer and has a high scratch resistant. If the surface does get scratched it is easy to repair. Sand the damaged area with 400 grit sandpaper. The aim is to feather out the scratch and prepare the repair area for to coating. Then wipe up the dust using neutral cleaner or rubbing alcohol. The repair area needs to clean dull and dry. When dry apply 2 or 3 thin coats of U140 . Allow 24 -48 hours before opening to vehicular traffic depending on temperature and humidity.

Penetrating sealers do not form a film at the surface. The work by blocking the pores in the concrete and restricting the oil and other contaminates getting into the sub surface of the concrete. The very top surface is still exposed however so staining is still possible and there are limitations to the amount of oil exposure the penetrating can withstand.

This depends on the amount of use, type of use, chemical exposure, and of course how well the finished surface is cleaned and maintained. Typically, you should expect to 3 to 5 years before having to do a recoat. Based on foot and vehicular traffic, floor should be swept clean with broom or a microfiber dusting pad.

In a workshop environment or where there is heavy vehicular traffic, floor surface should be mopped daily or cleaned with a floor machine using a neutral cleaning solution.

If the surface is polished (maximum 800 grit ) or very dense we recommend you apply a prime coat first. Apply the prime coat by pump up spray only. No mopping.

If the surface is very textured uneven or broom finished, then a U140 should be applied by 3/8th nap microfiber roller. Please refer to the technical datasheet for more in depth application instructions.

It is very important to make sure that the concrete is absorbent. Any existing sealer or curing agent etc. that might interfere with the absorption of the u140 sealer should be removed. A quick test for existing sealers is to conduct a water test to see if the concrete will darken when wet. Simply pour 1 fl.oz of water on the concrete and see if it will darken the surface after standing for 5 minutes. If after 5 minutes the surface does not darken prepare the surface by sanding the floor with a 60-200 grit sanding screen or diamond abrasive pad. Remove all residue before sealing.

What customers are saying

Related Products

CoverSeal AC250 WB Acrylic Natural Stone Sealer, Gloss Finish

Penetrating Concrete Sealer - CoverSeal Pen55 UV Resistant, Oil Repellent Coating